My apologies to my other blog readers who like to read about camping and motorhome stuff. I promise I will do some posts on that, especially the last three campgrounds we went to. But for now I am blogging about the barn loom, and adding links to my loom restoration and rug weaving groups on Facebook. I promise, more camping and RVing themed posts will come soon!

I received some wonderful emails from the gentleman and his wife who donated the old Finlander barn loom to the museum. They were very grateful to receive the rug that I completed from the half woven one left on the loom. We are not sure who started it. But I completed it and sent it on to them. They are going to send me some more information about their grandmother, Sanna, and some photos! How exciting!

In their emails, they have dubbed me: "Karen, Owner of The Kangas Loom". So I guess from herewith forward, the Finlander Barn Loom will be known as The Kangas Loom. I like that.

Last night I wound up 60 turns of warp, equaling about 40 yards. It's quite a technical process to get it all on evenly and under perfect tension. The more perfect the warp string is put on, the more perfect the final rug turns out.

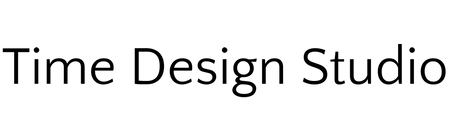

Here is my warping setup: a rack with 24 spools of warp, a tension box clamped to a sawhorse, and then the actual loom, pushed across the room to access the back side. Once it all set up, then I can push it back to the windows on the left side of the pic.

Section by section, I wind on the warp. Carefully watching the threads, making sure there aren't any knots, and they wind up evenly with no "snow drifts" that hamper the overall circumference of each layer as it winds on. The arches of plastic tubing help guide the threads into each section, without jumping the pegs into the next section. I "leap frog" the tubes from peg to peg as I move across the beam.

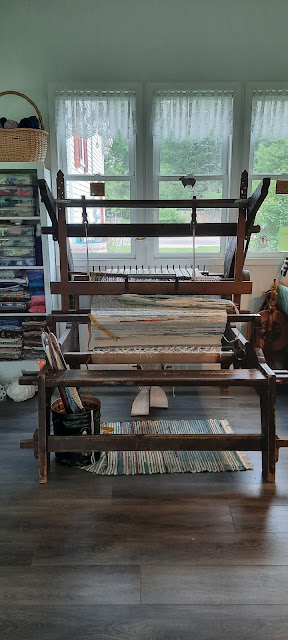

As each section reaches the same 60 turns, using a little digital thumb counting device from my friend Rosie Dupuy, a weaver of Bethel Missouri. She stores them in these little tins from mints. How cute!

I carefully tape the order of the threads down to the beam. I have learned that doubling the tapes works even better. And recently I have added a third piece of tape right where I cut the threads free. Then as I remove them one at a time to thread them into the loom, they are all in perfect order. No criss crossing, no tangles.

Ahhhhh a perfectly wound warp! It really makes my heart go Pitter Pat! I love to touch it and feel how even and symetrical it is. I know, I am weird, but sometimes the littlest things about weaving give me such enjoyment.

At this point, it was getting late. I would have to wait until the next morning to start the actual loom threading of the heddles and sleying of the reed. It's hard to quit and go to bed. Years ago, I would stay up until the middle of the night, working on things like this. And then get up and go work an 8 hour day, take care of 2 teens, sometimes 4 teens on the weekends, keep up a house and meals and laundry and dogs and all those tasks. Now that we are retired, I learn to pace myself, and get some sleep. LOL.

In the morning it was time to start "tying on"! That is where I take each little thread and tie it in order, onto the corresponding thread coming off the harnesses. This is the leftover warp from the last rug woven. By leaving the ends hanging, in order, on these two suspended lease sticks, I can just tie on the threads and not have to rethread each and every one through the harnesses and reed. A real timesaver.

Bit by bit, strand by strand, I tie each one one. Carefully untaping each section. I also count each section of 24 threads to be sure one isn't accidentally wedged down between the pegs. That can cause a REAL snarly situation, plus the count of threads would be off by 1 thread at the front end.

Because the last rug was only 24 inches wide, and I wanted the new ones to be wider, I had to tie up 72 more string heddles. It takes time, and I carefully tied each one on the "heddle tying jig" that came with the loom. For now we only tied them with warp string, doubled up. But I think in the future I will order some Swedish Seine Twine and tie ones that will last forever.

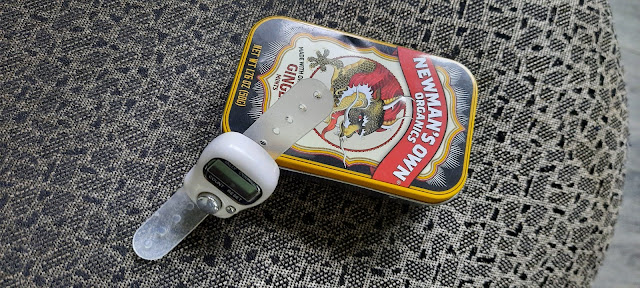

Little granddaughter Claire, 4 years old, was here to help me. What a great place to sit and tie heddles, right on the loom bench seat. Together. Just like the grandson of the original loom owner Sanna did. The grandson Ron, now in his 80's, remembers setting his little butt on the loom bench next to his grandmother.

Once the 72 heddles were in place, I had to carefully guide the remaining bouts of new warp through them, one at a time. Alternating the threads between harness one and harness two, the pattern of every other thread is obtained. Being careful... because if even one thread is mixed up or criss crossed or repeated instead of alternated, it can take some time to correct by pulling them back out till you reach the mistake and start over.

This morning it was finally time to start weaving an actual rug! I start with a few rows of scrap to get the warp spread out, evenly tensioned and checked for any errors. Then I weave in some creamy white "header threads" that later will be folded over and hemmed along the ends of the rug.

Little Claire hopped right up on the bench, just like 80+ year old Ron told us he did as a boy, by his grandmother Sanna's side. Carrying on the tradition of teaching and learning and enjoying the creation of something pretty and useful.

All of my seven grandchildren have learned to weave.

Claire is the youngest, and first to weave on this particular loom.

Just look at that little butt,

next to my big Grandma butt.

She helps with the rags and tells me what colors are coming next. She chooses which random shuttle is next for the rug, and helps untangle the rags if they get caught on the rod below.

She likes the idea of threads going Under Over Under Over. and looks closely at what we are creating. Steve snapped pics of us so we could weave together.

Before we know it,

another rug is born!

We are weaving this particular rug in the Finnish tradition of thinner rags and in a hit n miss fashion. Sometimes I weave thicker rugs with doubled rags or a thicker strip to start with. Sometimes I weave with thick strips of wool blankets. Sometimes with chained up sock loopers of factory waste. Sometimes I weave with all denim fabric.

Last summer I got boxes and boxes of prepared rag balls of thinner fabrics from a retired weaver, so we have a lot of thin rag balls to use up... and a lot of warp on the loom to use them up on.

And The Kangas Loom weaves again.